About us

Created to bring us together

Be Square is built for interactivity. As a fan you're tired of passively watching a livestream with no way to show your appreciation to the musicians, comedians or performers you're watching. As a performer, you're tired of playing to a camera, with no idea how your audience is feeling.

We believe the experience of a great performance is fundamental to who we are as people. By allowing audiences and performers to connect remotely in real time, we are creating an immersive and inspiring real-time event.

The platform is not intended to replace live performance but to push the streaming and virtual performance landscape to a new level.

Features

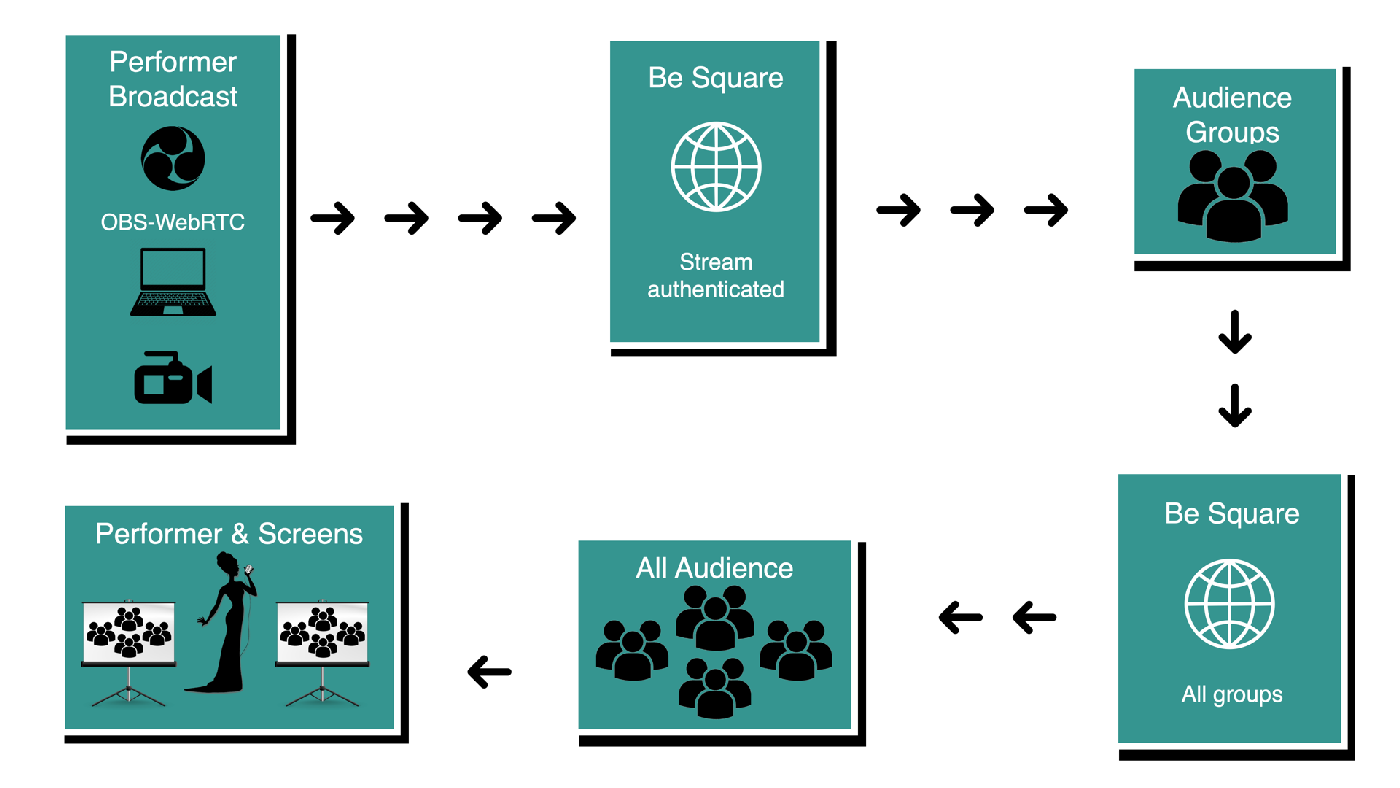

Be Square is the only platform that allows friends to interact in real time with each other in groups of up to six, whilst also watching and interacting in real-time with the performers.

Audience > performer interaction:

Be Square performers can see, hear and interact with their audience in real time.

We believe great performances are created when the audience and performer are as one, sharing the energy and vibe together.

Audience groups:

Audiences can attend Be Square shows alone or in groups of up to six people.

Allowing them to be with friends and enjoy the performance together whilst hearing the rest of the audience gives the user a near real-life event experience.

Be Square performers can see, hear and interact with their audience in real time.

We believe great performances are created when the audience and performer are as one, sharing the energy and vibe together.

Audiences can attend Be Square shows alone or in groups of up to six people.

Allowing them to be with friends and enjoy the performance together whilst hearing the rest of the audience gives the user a near real-life event experience.

How it works

Our best sessions

The Real Me

While some companies use their brand as an opaque facade to hide their questionable practices, others are opening up to their audience and sharing their true personality. The result is a more honest relationship with customers.

Find Your Own Voice

The 2013 SXSW keynote speech by the Foo Fighters frontman is based around creativity and finding your own voice. Highly inspiring to all creatives, whatever the discipline.

Another 10 Things You May Not Know About CSS

Lea talks about CSS secrets and lists 10 things you may not know about CSS.

News

During early testing we partnered with the Battersea Arts Center, London, who ran a weekend of shows ranging from stand-up and improv comedy to live music. Here are some articles and short video from that weekend.

Contact

Drop us a line - whether you're interested in a demo, or just want to have a cup of coffee with us.